Overview

ICMロガーの概要をここに記載

Data logger

Corrosion Monitor

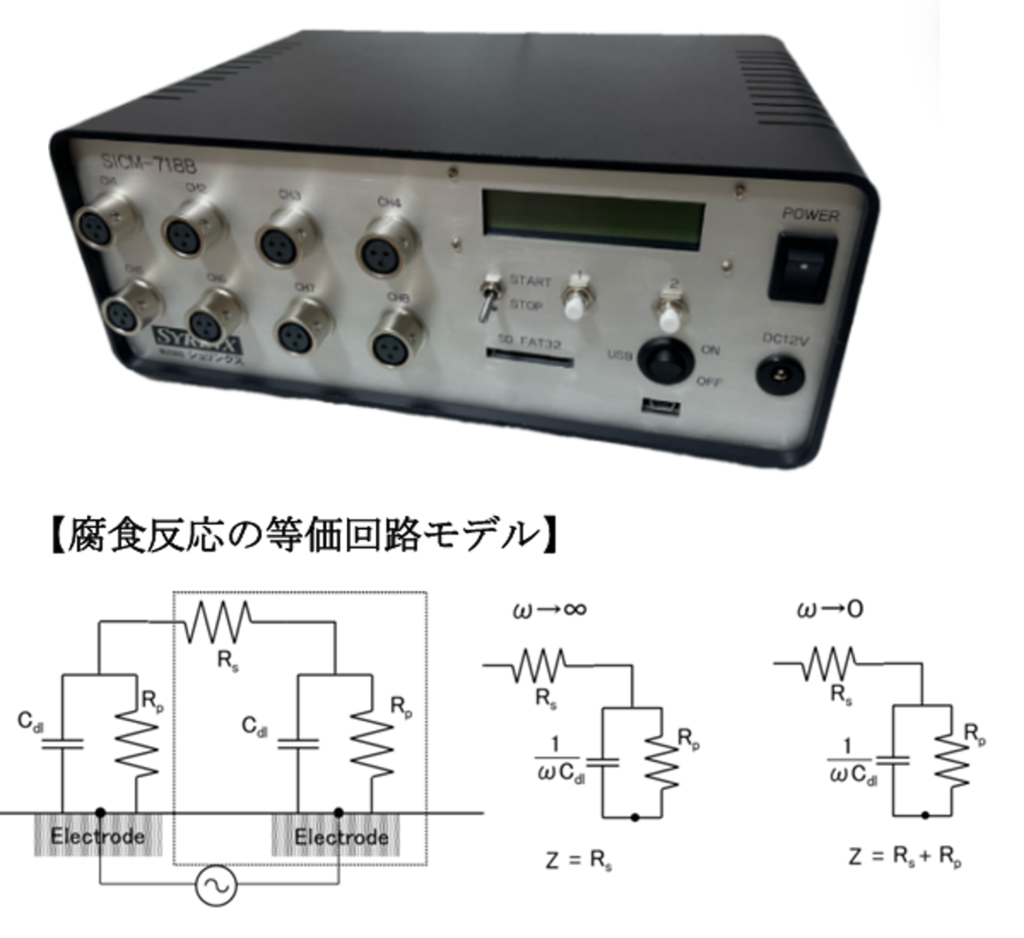

SICM-714B/718B

- Up to 4 (714B) or 8 (718B) ICM sensors can be connected

- It can be run on battery power or AC power

If you have any questions,

please feel free to contact us.

Appearance・Structure

Atmospheric corrosion systems under electrolyte immersion and a water film are represented by the equivalent circuit. Z is the impedance, Rp is the polarization resistance (∝ corrosion resistance), Cdl is the electric double layer capacitance, and Rs is the solution resistance. Since it can be approximated that Z ≒ Rs when ω→∞, and Z ≒ Rs + Rp when ω→0, the solution resistance Rs can be measured from the high frequency side, and the polarization resistance Rp can be calculated by subtracting value on the high frequency side from the value on the low frequency side. The inverse of the polarization resistance is correlated with the corrosion rate. Therefore, it is possible to grasp the change in the corrosion rate over time.

Specification

Measurement Channels

SICM-714B: Max.4 SICM-718B: Max.8 ※Can be expanded

Measurement frequency

High frequency side: 10kHz

Low frequency side: Select from 1mHz, 10mHz, 100mHz *Can be changed (Consultation required)

Applied voltage

Sine wave, Select 20mVp-p, or 100mVp-p

Impedance measurement range

High frequency ~105Ω, Low frequency ~109Ω

How to measure

AC impedance measurement with DFI

Noise reduction

Noise cancellation by integrating 1 to 8 cycles,

Noise removal with shield/guard function, Cable stray capacitance cancellation

Measurement interval

10 min. *Can be changed

Recorded data

Time, Solution resistance“Rs”, Corrosion resistance “Rc”, Electric double layer capacitance “Cdl”, Phase difference

Data format

Text (Can be read by spreadsheet software, etc.)

Data storage

SD card (4 ~ 32 GB)

Power supply

100V AC adapter or 12V battery

Weight

SICM-714B: App.1.7kg SICM-718B: App.1.9kg

Size

260mm(W) x 180mm(D) x 100mm(H) (Excluding protrusions)

Installation Locations

Paint coating

Coating degradation and undercoating corrosion.

Plumbing

Galvanic corrosion between dissimilar metals

Ship

Salt damage from seawater

Bridge

Infrastructure Corrosion

Papers (Japanese)

- Fe/Fe対ICMセンサによる亜鉛アルミ複合被膜の防錆挙動解析

- インピーダンス測定による塗膜劣化挙動モニタリング

- Fe/Fe 対ICM センサによるジンクリッチ塗料のインピーダンス挙動解析

- Fe/Fe 対 ICM センサを用いた塗装のインピーダンス挙動解析の検討

- Fe/Zn/Al 対 ICM センサによる 3 種の金属のガルバニック腐食挙動解析

- Al/Al 対 ICM センサを用いたアルミニウムのインピーダンス腐食挙動解析

- 交流インピーダンス法によるアルミニウムの腐食モニタリング