Overview

AC impedance measurement of metal film corrosion and coating degradation behavior.

Atmospheric corrosion monitoring is generally performed using a pair of sensors with two electrodes, such as a plate, concentric circle, or comb-shaped sensor.

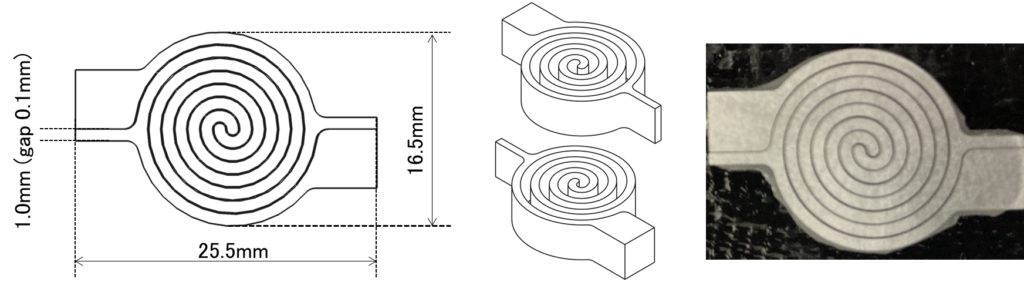

The width, spacing, and facing length of the two electrodes greatly affect the accuracy of the measurement. Therefore, the electrodes are improved to a spiral shape to improve machining and measurement accuracy.

Sensor types

We provide various types of sensors for your purpose.

It can be customized to meet your requirements.

Spiral Type

- Spiral-shaped electrode improves measurement accuracy

Concentric Type

- Electrodeposition coating on electrode sides

Appearance・Structure

It has a flange structure to suppress movement in the rotational direction in a spiral shape, with an electrode width of 1 mm and a distance between electrodes of 0.1 mm. This shape eliminates directional dependence of the mounting angle and captures corrosion behavior on average. The gaps between electrodes are filled with epoxy resin and treated with metal surface to suppress crevice corrosion.

Specification

Materials

Carbon Steel, Stainless Steel, Aluminum Alloy, Magnesium Alloy etc.,

The area of electrodes

1cm² × 2 pieces

Lead Wire

1.5m Attached to the side of the electrode flange

Connection to Measuring

Equipment

・Corrosion monitor SICM-714B, SICM-718B (Impedance)

・ACM data logger SACM-312B/314B, SACM-31FB etc,.(Galvanic)

Heat resistant temperature

Sensor…150℃ Lead wire…60℃

※Specification can be modified

Installation Locations

Coating film

Coating degradation and undercoating corrosion.

Plumbing

Galvanic corrosion between dissimilar metals

Ship

Salt damage from seawater

Bridge

Infrastructure Corrosion

Papers (Japanese)

- Fe/Fe対ICMセンサによる亜鉛アルミ複合被膜の防錆挙動解析

- インピーダンス測定による塗膜劣化挙動モニタリング

- Fe/Fe 対ICM センサによるジンクリッチ塗料のインピーダンス挙動解析

- Fe/Fe 対 ICM センサを用いた塗装のインピーダンス挙動解析の検討

- Fe/Zn/Al 対 ICM センサによる 3 種の金属のガルバニック腐食挙動解析

- Al/Al 対 ICM センサを用いたアルミニウムのインピーダンス腐食挙動解析

- 交流インピーダンス法によるアルミニウムの腐食モニタリング